Catalyzing materials research across Wisconsin

Throughout the University of Wisconsin System, there is a wealth of materials expertise, equipment and research facilities — but connecting those resources across campuses and between academia and industry often depends on serendipity and informally built connections.

“There are so many collaborations that come about because you met someone at a conference and they’re doing something related to what you’re doing or have capabilities you’re looking for,” says Gokul Gopal, an assistant professor of engineering physics at UW-Platteville. “It tends to happen through almost random encounters rather than a systematic portal that allows you to access information in a smoother manner.”

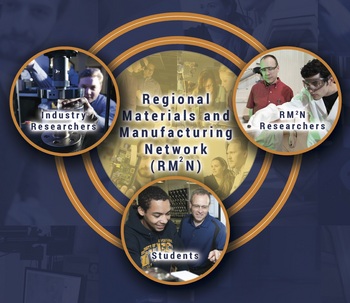

Partners across the system are filling that void through the recently established Regional Materials and Manufacturing Network (RM2N). The network is currently developing features on its website to allow academic and industrial partners from all over Wisconsin to list and search for the resources they have and need, to advance materials science and engineering through both academic research and the development of new products. The initial member campuses in the network are UW-Eau Claire, UW-La Crosse, UW–Madison, UW-Milwaukee, UW-Platteville, UW-Stevens Point and UW-Stout.

The network will help all the institutions involved expand their efforts and make the most of what’s already here in the state. “I think part of it is, to do what we do in materials science is expensive,” says Doug Dunham, director of the Materials Science Center at UW-Eau Claire. “Instrumentation in particular is very expensive. It doesn’t make sense in many cases for multiple copies of one type of instrument to be located at seven different campuses in Wisconsin. Instead, let’s make it so someone has it but everyone has access to it.”

“It’s a way for us to help industry, for example, without saying, ‘No, we can’t help you because we don’t have it.’ We can still help even if it’s not coming directly from us.”

Doug Dunham

Gopal points out that UW-Platteville is looking for more academic and industrial users for its recently established nanomaterials lab, but also wants to help its students and partners take more advantage of the kinds of resources and specialized instrumentation and facilities that exist across the UW System. He’s hoping the new network will help him develop a one-week course in which Platteville students can get hands-on instruction in facilities like the clean rooms in the Engineering Centers Building in Madison.

While researchers on each UW System campus interact with different Wisconsin companies in different sectors of industry, Dunham thinks the network will make all those partnerships more fruitful. “It’s a way for us to help industry, for example, without saying, ‘No, we can’t help you because we don’t have it,'” Dunham says. “We can still help even if it’s not coming directly from us.”

The network is particularly interested in collaboration around computation. Through advanced simulation, mathematical software, cloud storage, big data, informatics and many other developments, computation is transforming materials and manufacturing research and education. The network is working to promote the tools and opportunities of this rapidly changing field within the collaboration and beyond.

Dane Morgan

Thomas Kuech

“Computing is a particularly exciting area because with cloud resources, we can now partner more easily on computational activities than ever before, and there is enormous opportunity for us to work together in this space,” says Dane Morgan, the Harvey D. Spangler Professor of Engineering and Professor of Materials Science and Engineering at UW–Madison.

Thomas Kuech, the Milton J. and A. Maude Shoemaker and Beckwith-Bascom Professor of Chemical and Biological Engineering at UW–Madison, says he sees opportunities in particular for UW–Madison to share its resources and expertise more broadly, and for the partnership in general to benefit industrial partners such as those in the plastics and packaging industries.

“You want to make something that’s more than just a bunch of parts,” Kuech says. “If you follow the Wisconsin Idea, you want to provide communication and benefit to industry and the people of the state, and that’s what we’re trying to do with this network.”

Subscribe to Wisconsin Ideas

Want more stories of the Wisconsin Idea in action? Sign-up for our monthly e-newsletter highlighting how Badgers are taking their education and research beyond the boundaries of the classroom to improve lives.