Physical Sciences Lab is a one-stop shop

As full-time caretaker for Wisc-SIMS, one of the geology department’s most intricate scientific instruments, Jim Kern is no stranger to trouble-shooting problems and making repairs. Still, when the machine, called an ion microprobe, sprang a leak in its detector this summer, the technician soon realized he’d need help from the instrument’s French manufacturer to fix it

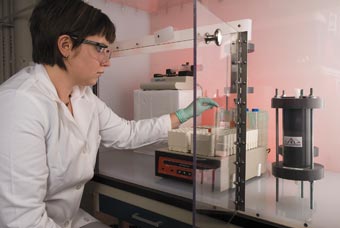

Jamie Stietz, a researcher in the laboratory of soil science professor Sharon Long, works with a soil column built by the Physical Sciences Laboratory. For her studies of how microbial contaminants of drinking and recreational water move through the soil, Stietz packs the column with various types of soil and sand, adds microorganisms, washes the column with water and then tests for the microbes’ presence in the effluent.

Photo: Bob Rashid

So Kern booked a flight to France, and hired the UW–Madison’s Physical Sciences Laboratory (PSL) to build a special shipping crate for the delicate part. But then the lab’s personnel did something that threw a wrench into his plans: Before they packed the component up, they studied it and came up with ways to repair it.

“Long story short, I didn’t need to go to France and we didn’t have to ship the part to France,” says Kern. Instead, he was able to get the ion microprobe up and running again and much faster than expected. The geology department is also now discussing possible improvements to the detector’s design with PSL.

“PSL really came through in this scenario,” he says. “And if we do redesign the part, we want them involved, because we feel that strongly about their services and expertise.”

One part research and development laboratory and one part machine shop, PSL has been offering its know-how in design, manufacturing and instrument calibration to UW–Madison (and beyond) for some 40 years. From its cavernous, metal building in the cornfields outside Stoughton, it has also had a hand in some of the most ambitious scientific experiments of our time, including the giant neutrino telescope, IceCube, currently under construction in Antarctica, and the Large Hadron Collider, which began operations this fall in Geneva, Switzerland.

But over the years, PSL’s 40-plus staff members have also built hundreds of smaller pieces of equipment for researchers, including seed coaters, soil columns, surgical tools, monitors for speech therapy, specialized magnets, rainwater samplers — the list goes on and on. They’re now hoping that even more people will take advantage of their ability to make nearly any kind of electronic, mechanical and machined gadget under the sun.

“We’ve done 6,000 to 7,000 projects, and no two of them are alike,” says Farshid Feyzi, who has been with PSL since 1983 and was recently named director. “But what’s common about them is that they’re all fun and things that people need.”

One group that has made ample use of PSL is the Geological Engineering Program. During the past five years or so, its faculty, staff and graduate students have commissioned dozens of devices for testing new materials and methods in landfill design and construction, including pressure plate extractors, permeameters and consolidation cells. And while many of these items resemble commercial equipment — and each other — they encompass a range of features that simply can’t be found in a supplier catalog.

“Everything we have from PSL kind of looks the same,” laughs researcher Sabrina Bradshaw, as she surveys a room cluttered with equipment bearing the lab’s logo. “But we do run several different kinds of tests in these, so they come in very handy.”

“The advantage of using PSL is that we can specify exactly what we need our equipment to do,” adds doctoral student Ron Breitmeyer. “So we’re able to design the equipment around our experiments, instead of having to design experiments around the available equipment.”

In Breitmeyer’s case, this has meant creating detailed engineering drawings, which PSL’s machinists then use to build equipment to his precise specifications. But Feyzi emphasizes that his staff is equally capable of starting from simple back-of-the-envelope plans, or just an idea for a new device.

Although he also admits that sometimes the lab isn’t able to help, Feyzi encourages anyone who’s interested to make an appointment for a consultation, or simply stop by PSL’s new office on the main UW–Madison campus. Visit the Physical Sciences Calendar for office hours and location.

As for Kern, he’ll definitely be tapping PSL’s expertise in the future. Not only does he plan to take advantage of staff experience with cleaning sensitive, ultra-high vacuum parts, but he may also collaborate with them to improve the Wisc-SIMS instrument.

“Working with PSL has been a very rewarding experience,” he says. “If we want to redesign a component, it’s comforting to know that PSL has all the necessary personnel to do that.”